The Importance of Quality Control in Circuit Board Assembly Services

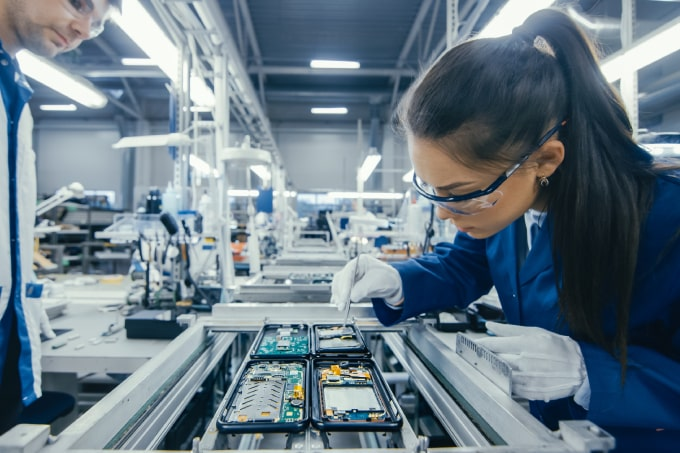

Circuit boards are the backbone of modern technology, powering everything from smartphones to medical devices. The process of assembling these intricate components is a complex and precise task. Here, quality control isn’t just a buzzword—it’s a critical factor that can make or break the performance and reliability of electronic devices. Let’s dive into why quality control in circuit board assembly services is so crucial.

What is Quality Control?

Quality control (QC) refers to the set of procedures implemented to ensure that a manufactured product adheres to a defined set of quality criteria or meets the requirements of the client or customer. In the context of circuit board assembly, QC involves meticulous checks and balances at various stages to ensure the boards function correctly and reliably.

The Role of Quality Control in Circuit Board Assembly

Ensuring Reliability and Performance

Imagine your smartphone failing because a tiny component on its circuit board was incorrectly placed. Quality control ensures that each part of the board performs its intended function, ensuring the overall reliability and performance of the final product.

Preventing Costly Errors and Rework

Errors in circuit board assembly can be incredibly costly, both in terms of money and time. Quality control helps catch these errors early in the process, preventing the need for extensive rework or, worse, scrapping entire batches of boards.

Key Components of Quality Control in Circuit Board Assembly

Inspection and Testing Procedures

Inspection and testing are the cornerstones of QC in circuit board assembly. These procedures are designed to identify defects and ensure each board meets the required standards before moving on to the next stage.

Standards and Certifications

Compliance with industry standards and certifications, such as those from the IPC (Institute for Printed Circuits) and ISO (International Organization for Standardization), is essential. These standards provide a framework for quality and reliability that manufacturers must adhere to.

Inspection Procedures in Circuit Board Assembly

Visual Inspection

Visual inspection involves manually checking the boards for obvious defects. This can include looking for soldering issues, component misplacements, or other visible errors.

Automated Optical Inspection (AOI)

AOI uses cameras and software to automatically inspect the boards. This method is much faster than manual inspection and can catch errors that the human eye might miss.

X-ray Inspection

X-ray inspection is used to check the internal structure of the boards, such as the solder joints and hidden components. This is crucial for detecting hidden defects that other methods might not catch.

Testing Procedures in Circuit Board Assembly

In-Circuit Testing (ICT)

ICT involves testing the electrical performance of individual components on the board. It ensures that each part is functioning correctly and is correctly placed and soldered.

Functional Testing

Functional testing checks the overall operation of the assembled board. It simulates real-world usage to ensure the board performs as expected.

Burn-In Testing

Burn-in testing subjects the boards to extreme conditions, such as high temperatures and voltages, to catch early failures and ensure long-term reliability.

Standards and Certifications in Circuit Board Assembly

IPC Standards

IPC standards are globally recognized guidelines for the manufacture of electronic assemblies. Adhering to these standards ensures high quality and reliability.

ISO Certifications

ISO certifications, such as ISO 9001, provide a framework for quality management systems. Companies with these certifications demonstrate their commitment to maintaining high standards.

Benefits of Implementing Quality Control in Circuit Board Assembly

Improved Product Reliability

Quality control ensures that each circuit board functions as intended, significantly enhancing the reliability of the final product.

Enhanced Customer Satisfaction

When products are reliable and perform well, customer satisfaction naturally increases. This leads to repeat business and a strong reputation in the market.

Cost Savings

By catching errors early and ensuring high quality, companies can save on costs associated with rework, recalls, and warranty claims.

Challenges in Quality Control for Circuit Board Assembly

Complexity of Modern Circuit Boards

As circuit boards become more complex, ensuring their quality becomes more challenging. Each component and connection must be precisely checked, adding to the QC workload.

Keeping Up with Technology Advancements

Technology is always advancing, and QC methods must evolve to keep pace. This requires continuous investment in new tools and training for staff.

Technological Advances in Quality Control

Role of AI and Machine Learning

AI and machine learning are revolutionizing QC by enabling more sophisticated inspection and testing methods. These technologies can analyze vast amounts of data to identify patterns and predict potential issues.

Advanced Inspection Tools

New tools, such as 3D AOI systems and advanced X-ray machines, are improving the accuracy and efficiency of inspections, helping to catch even the smallest defects.

Case Studies: Success Stories in Quality Control

Example 1: A Consumer Electronics Company

A leading consumer electronics company implemented advanced AOI and X-ray inspection techniques, reducing their defect rate by 30% and saving millions in rework costs.

Example 2: A Medical Device Manufacturer

A medical device manufacturer adopted comprehensive QC procedures, including functional and burn-in testing. This led to a significant increase in product reliability, crucial for their life-saving devices.

Quality Control Best Practices for Circuit Board Assembly

Comprehensive Training Programs

Ensuring that all staff are well-trained in the latest QC procedures and tools is vital. Continuous training programs help maintain high standards and adapt to new technologies.

Continuous Improvement Strategies

Adopting a mindset of continuous improvement ensures that QC processes are always evolving. Regular reviews and updates to procedures can help catch new types of defects and improve overall quality.

The Future of Quality Control in Circuit Board Assembly

Emerging Trends

Emerging trends, such as the use of big data and IoT (Internet of Things) devices in QC, are set to revolutionize the industry. These technologies will enable even more precise and efficient quality control processes.

Predictions for the Next Decade

Over the next decade, we can expect QC in circuit board assembly to become even more automated and data-driven. AI will play a significant role, predicting and preventing defects before they occur.

Mitigating Legal Risks

In addition to enhancing product reliability and reducing costs, quality control also plays a crucial role in mitigating legal risks. For instance, some mobile companies have faced class action lawsuits due to widespread issues due to battery defects that led to overheating and fires. Class action lawsuit are lodged against a company if a group of people have been injured because of the same defendant and compensation received under such class action settlement gets distributed to all the individuals fighting and in some no proof class action lawsuits leads to compensation for plaintiff without showing a proof like a payment slips and other stuff but By implementing rigorous QC procedures, manufacturers can identify and resolve defects early, preventing similar issues that could lead to legal disputes. This proactive approach helps protect both the company’s reputation and its financial stability.

Conclusion

Quality control in circuit board assembly is not just about preventing defects—it’s about ensuring that the final products are reliable, efficient, and capable of meeting customer expectations. As technology advances, so too must our QC processes. By investing in advanced tools, adhering to standards, and continuously improving our methods, we can ensure that our circuit boards are of the highest quality, driving the success of the devices they power.

Leave a Reply