Internet of Things integration for real-time system monitoring

AI is changing how legal teams analyze contracts faster than ever before. The 2025 Generative AI in Professional Services Report shows that companies using GenAI across their operations have doubled in the last year. Legal teams have steadily adopted AI since its breakthroughs in 2016. A 2024 LexisNexis survey reveals that AI adoption has more than doubled in recent months.

AI’s effect on contract review proves most valuable for legal teams who handle third-party agreements. Recent data shows 58% of in-house lawyers used AI to review contracts last year. Another 40% plan to adopt it soon. Legal teams now see the real benefits of automated contract analysis software. The number of legal professionals using GenAI has jumped to 26% from 14% in 2024. This jump shows major improvements in efficiency and productivity for legal practices. Modern AI tools help teams review agreements faster, spot risks more accurately, and stay aligned with internal playbooks.

This piece looks at how IoT integration improves live monitoring of contract analysis systems. It covers the architecture, data flow processes, real-life applications, and challenges that organizations face with these technologies.

Understanding IoT in Real-Time Monitoring Systems

IoT technologies have transformed up-to-the-minute monitoring systems. Smart environments now exist where data flows non-stop. This allows quick insights and responses across many industries.

Definition of Real-Time Monitoring in IoT Context

Up-to-the-minute monitoring in IoT means getting constant data streams from connected devices almost instantly. Users can spot problems, performance issues, and critical events right away. Modern IoT monitoring beats older systems by using smart sensors that talk over the internet. This makes data sharing and analysis happen instantly.

IoT monitoring’s main job is to turn raw data into practical information without delay. The process works in three steps: finding all IoT devices, watching performance metrics non-stop, and sending automatic alerts when specific conditions happen.

Up-to-the-minute IoT systems track several data types at once:

- Performance metrics like bandwidth usage and response time

- Health status indicators including device uptime and battery life

- Security data such as unauthorized access attempts

- Environmental conditions including temperature and humidity

By 2025, the global IoT market is projected to reach approximately £1.27 trillion, and more than 75 billion connected devices will create and send data. These numbers show why expandable up-to-the-minute monitoring solutions matter.

Key Differences Between Traditional and IoT-Based Monitoring

Traditional and IoT-based monitoring systems work differently in vital ways. Both want to run operations well, but IoT monitoring brings special benefits.

Old-school monitoring follows fixed schedules and rules. IoT systems use live data to make decisions, which creates better management. Companies can spot problems before they cause shutdowns or lost money.

Growth potential sets these systems apart too. Old systems hit walls when expanding and need big upgrades. IoT monitoring grows easily and connects thousands of assets across many locations.

These systems control things differently as well. Old setups run everything from one place. IoT monitoring lets you control things from anywhere using apps. Managers can check and adjust their systems using phones or computers.

Data collection works differently too. Old monitoring needs manual checks and reports. IoT systems grab data automatically all the time. This makes a big difference in response time. Old systems find issues after they happen. IoT spots problems right away.

IoT monitoring does face some challenges. It uses lots of power and drains batteries. But the benefits of instant insights, better decisions, and smoother operations keep pushing its growth across many fields.

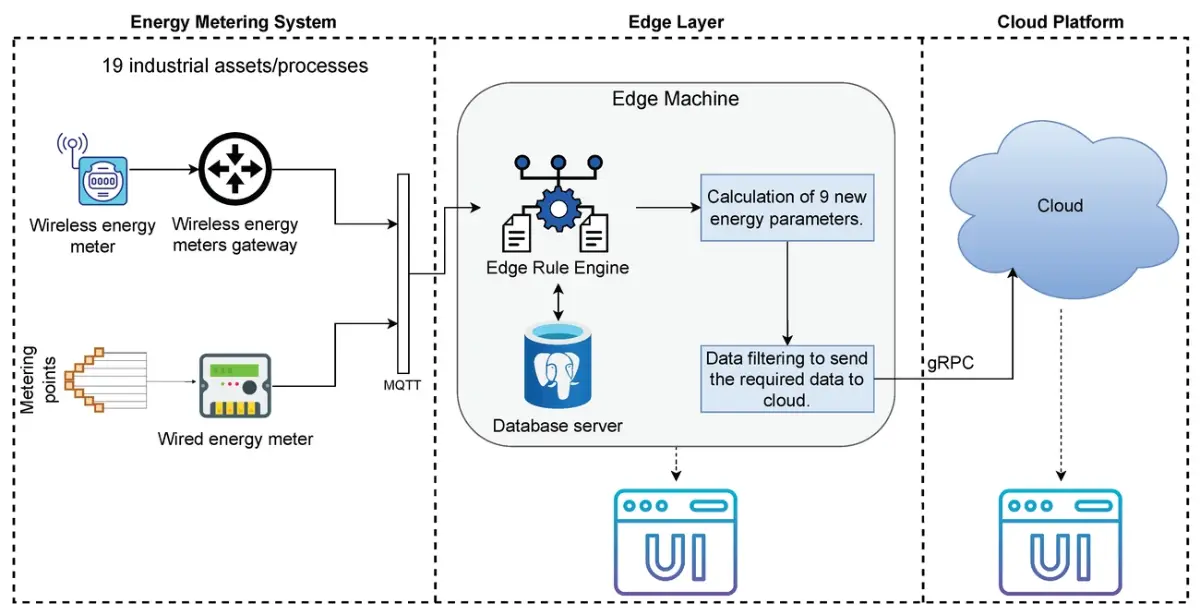

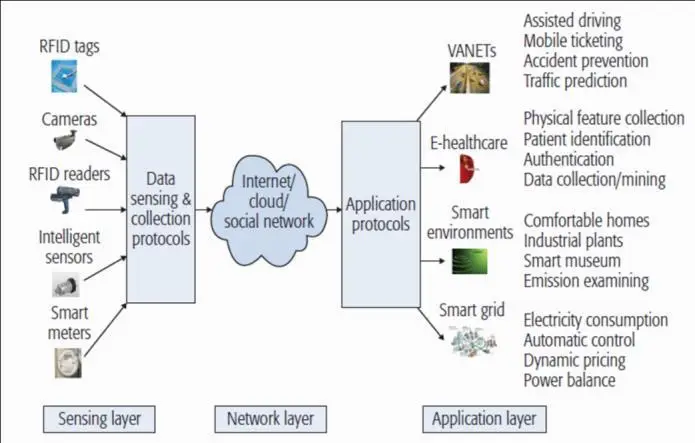

Core Components of IoT Integration Architecture

IoT-based real-time monitoring relies on three connected layers that work together. Each layer plays a vital part in collecting, sending, and analyzing data. A clear understanding of how these parts work together creates a continuous flow of information from physical environments to useful insights.

Sensor Nodes and Edge Devices

Sensor nodes and edge devices are the foundations of any IoT architecture in the perception layer. These sensors act as the system’s eyes and ears. They capture environmental changes and send this information to processing centers. The sensors collect data about temperature, moisture, motion, noise levels, and air quality. Actuators work alongside sensors as “movers” that turn digital signals into physical actions. A good example is adjusting a thermostat when temperatures get too high.

Edge devices show the progress in IoT architecture by processing data closer to its source. Unlike basic IoT devices with basic processing power, edge devices can analyze information right where they are. This is a big deal as it means that these devices reduce delays and save bandwidth. Industrial machinery equipped with vibration sensors and processing chips can spot problems right away instead of sending raw data to distant servers.

Smart sensors take this capability further by using AI or machine learning algorithms right on the device. This built-in intelligence analyzes data without sending every piece of information, which saves network resources while staying responsive. By 2025, the digital world will include over 15 billion connected devices. This massive growth makes edge processing essential to manage such a large, spread-out system.

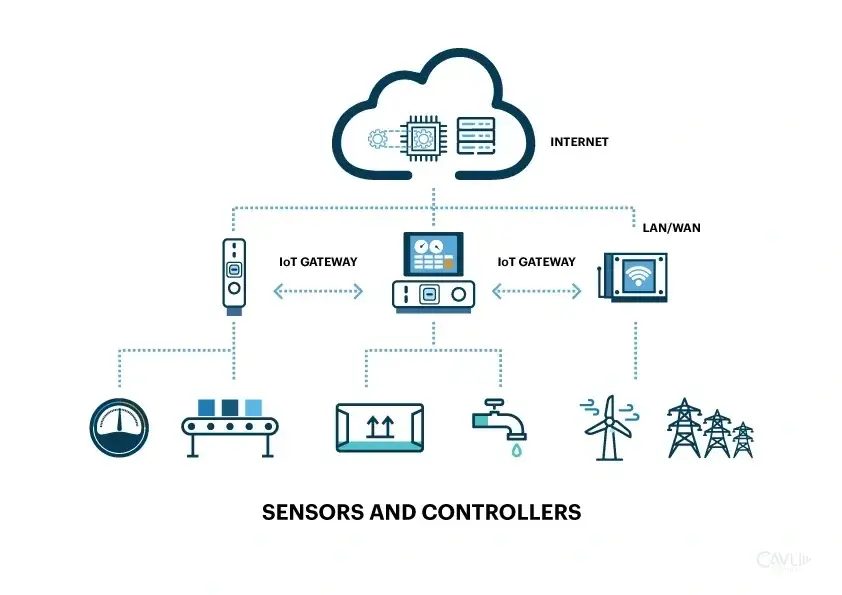

IoT Gateways and Protocol Translation

IoT gateways are vital links between sensor networks and larger data processing systems. They gather data from IoT sensors and convert device-specific protocols into standard formats that work with cloud or on-premise systems. These gateways bridge the gap between the perception layer and data processing infrastructure.

Gateways do more than just pass along data. Their key functions include:

- Converting protocols so different devices and platforms can work together

- Filtering and combining data to remove extra information

- Setting up encryption and authentication for secure data transfer

- Processing data quickly for time-sensitive uses

IoT Edge devices can work as gateways in two main ways. The transparent gateway pattern lets devices keep their IoT Hub identities while connecting through the gateway. The translation gateway pattern helps devices that can’t connect directly to IoT Hub by converting their messages into compatible formats.

Today’s gateways support many communication protocols like MQTT, CoAP, HTTP, Zigbee, and Z-Wave. This flexibility helps integrate different device systems. Such versatility matters because IoT systems will use many devices with different network technologies and communication standards by 2025.

Cloud and On-Premise Data Aggregators

Data aggregators make up the final layer where information from edge devices and gateways gets stored, processed, and analyzed. Companies can pick cloud-based solutions, on-premise systems, or a mix of both based on what they need.

Cloud-based aggregators use remote servers run by providers like AWS, Microsoft Azure, or Google Cloud. These solutions grow easily with device fleets, start up quickly, avoid big upfront costs, and provide powerful analytics tools. Cloud platforms adjust to changing needs, which works well for organizations that have varying workloads or expect rapid growth.

On-premise aggregators run completely within a company’s local infrastructure. Companies that handle sensitive data or have strict data rules often choose this approach. These solutions let companies customize everything to fit their specific needs, though they cost more to set up and maintain.

Many organizations now use hybrid models that combine both approaches. They process sensitive data locally while using cloud services for less critical information and advanced analytics. This balanced approach provides both security and the processing power of cloud platforms.

How IoT Enables Real-Time Data Flow

IoT-based monitoring systems work best when data moves continuously from physical environments to decision-making centers. Modern technologies need ultra-low latency to respond instantly in real-time systems.

Modern IoT ecosystems often use a unified digital layer that brings together digital data, location intelligence, and live analytics. When paired with scalable di

Data Acquisition and Transmission Pipeline

The IoT data acquisition process starts at the perception layer. Sensors collect environmental information and send it through a structured pipeline. This system revolutionizes traditional monitoring and makes device integration easier in different applications. Data typically flows from sensor nodes through gateways to cloud or on-premise aggregators. This creates a steady stream of useful information.

Time sensitivity plays a crucial role in data acquisition pipelines. To cite an instance, see manufacturing environments where robots monitor production lines – even small delays can reduce system effectiveness by a lot. Developers create customizable collection intervals to solve this challenge. Devices collect data every 15 seconds and update analytics platforms every 2 minutes in real applications.

The acquisition pipeline balances data completeness with transmission speed. Edge devices now do initial processing and filter unnecessary information before transmission. This method saves bandwidth while keeping data intact. Time-critical applications in the energy sector use this approach, where smart grids depend on up-to-the-minute data analysis to prevent overloads.

Low-Latency Communication Protocols (MQTT, CoAP)

Real-time IoT applications rely on specialized communication protocols that minimize transmission delays. Two protocols excel in restricted environments:

MQTT (Message Queuing Telemetry Transport) uses a publish-subscribe model that makes many-to-many communication easier. It runs on TCP and uses a broker-based architecture. Publishers send messages to topics while subscribers get updates from their chosen topics. MQTT gives three Quality of Service levels, which balance delivery assurance with performance.

CoAP (Constrained Application Protocol) follows a request-response model like HTTP but runs on UDP. This results in quicker data sharing with less overhead. The protocol ensures message delivery through retransmission and lets clients get automatic updates when resource states change.

These protocols each have their strengths. MQTT provides better reliability with slightly more overhead, making it perfect for critical applications. CoAP works best in limited bandwidth environments and offers multicast features not found in TCP-based options.

Real-Time Analytics with Stream Processing Engines

Stream analytics engines turn raw data into useful information at processing centers. These engines handle massive amounts of streaming data within milliseconds and spot patterns from multiple sources. Azure Stream Analytics can process millions of events each second with minimal delay.

Organizations use stream processing engines to spot anomalies, predict failures, and trigger automated responses without human input. Manufacturing plants analyze sensor data to detect temperature changes or strange vibrations. This prevents equipment failures before downtime occurs. Energy companies also use these systems to balance supply and demand in real time.

Modern analytics platforms can run in the cloud or on edge devices. Users can process data wherever it works best – remote servers handle complex analysis while edge devices manage immediate responses. The hybrid model combines both approaches and enables sophisticated real-time monitoring across distributed systems.

Use Cases of IoT-Based Real-Time Monitoring

IoT-enabled monitoring solutions now operate in multiple industries and change operations through continuous data collection and analysis. These ground implementations show how real-time monitoring creates measurable value in a variety of operational environments.

Predictive Maintenance in Manufacturing

Manufacturing industries lead the adoption of IoT-based predictive maintenance. Machine sensors collect vital operational data such as temperature, vibration levels, supply voltage, and current. This information travels wirelessly to centralized cloud storage platforms. AI and machine learning algorithms help maintenance teams analyze this data to forecast equipment failures.

This proactive approach brings substantial benefits through lower maintenance costs and improved asset reliability. Manufacturers can spot potential errors before they happen, which minimizes unexpected downtime and improves operational efficiency. Equipment sensors provide continuous feedback that helps maintenance teams plan optimal inspection routines and avoid emergency repairs that get pricey. Machine utilization rates and overall profitability increase as a result.

Remote Patient Monitoring in Healthcare

IoT monitoring has revolutionized patient care delivery in healthcare. IoT healthcare systems use non-invasive sensors to collect detailed physiological information that lets physicians monitor patients remotely in real-time. This capability proves especially valuable for the aging population, projected to represent more than 20% of the U.S. by 2030.

Industry reports show that over 60 million Americans will make use of remote patient monitoring by 2024. This technology strengthens individual-specific care by tracking vital signs like blood pressure, oxygen levels, and heart rate continuously. Physicians can make informed decisions, step in earlier, and prevent complications thanks to this ongoing monitoring. Remote monitoring systems also cut healthcare costs by preventing unnecessary hospital admissions and emergency room visits.

Smart Grid Monitoring in Energy Sector

IoT technologies allow power system components to be monitored and controlled in real-time within energy distribution networks. IoT modules work as communication gateways that gather and send data from installed sensors to track power generation equipment, substations, and distribution networks.

Quick response during outages becomes possible through this constant surveillance. Intelligent algorithms analyze data from multiple sources to find disruption causes and restore power quickly. IoT sensors also help integrate distributed energy resources like photovoltaic systems and wind power by providing real-time system condition data. Grid reliability improves through predictive maintenance and optimized energy distribution.

Fleet Tracking in Transportation

Transportation companies use IoT for detailed fleet monitoring to optimize operations. IoT-enabled telematics devices deliver instant data about vehicle location, speed, and route. This information helps fleet managers reroute vehicles to avoid traffic or hazards.

IoT sensors track vehicle components like engine health, tire pressure, and brake wear constantly. Managers can predict maintenance needs by analyzing this data, which prevents breakdowns and cuts repair costs. Research shows IoT-based tracking systems can lower fuel costs by up to 30% and boost fleet productivity by 25%. These systems also improve safety by monitoring driver behavior such as speeding, harsh braking, and sudden acceleration.

Popular Platforms and Tools for IoT Monitoring

IoT monitoring is dominated by several major platforms that offer specialized tools to blend systems and analyze data in real time.

AWS IoT Core and Greengrass

AWS IoT Core works as a central hub that connects devices securely. The platform supports billions of devices through its Device Gateway and handles MQTT, HTTP, and WebSocket protocols. The service authenticates and connects while routing messages between devices and AWS cloud services. Device Shadow stores each device’s current or desired state and lets users change settings even when devices are offline.

AWS Greengrass brings cloud features to edge devices and runs Lambda functions locally with minimal delay. This setup processes data right at the source instead of sending it to distant servers. The platform has complete monitoring tools like CloudWatch Logs, CloudTrail Log Monitoring, and system health telemetry. AWS Distro for OpenTelemetry works with Greengrass to collect and send telemetry data from edge applications.

Azure IoT Hub with Stream Analytics

Microsoft’s ecosystem uses Azure IoT Hub as its core service to connect and manage devices. The standard tier supports messaging between devices and cloud, and device twins store current and desired device properties.

Azure Stream Analytics handles large amounts of streaming data quickly, with delays under a millisecond. SQL-based query language with time constraints helps analyze moving data. The service ensures each event processes exactly once and supports Availability Zones for reliability.

Google Cloud IoT with Pub/Sub Integration

Google Cloud IoT Core has two main parts: Device Manager configures devices while Protocol Bridge connects through MQTT and HTTP protocols. The platform sends data streams to Cloud Pub/Sub, which passes messages with delays around 100 milliseconds.

This setup lets IoT devices send large amounts of data while spreading messages across multiple applications that process in parallel. Google’s solution shines when edge devices need to stream high volumes of data to cloud analytics services.

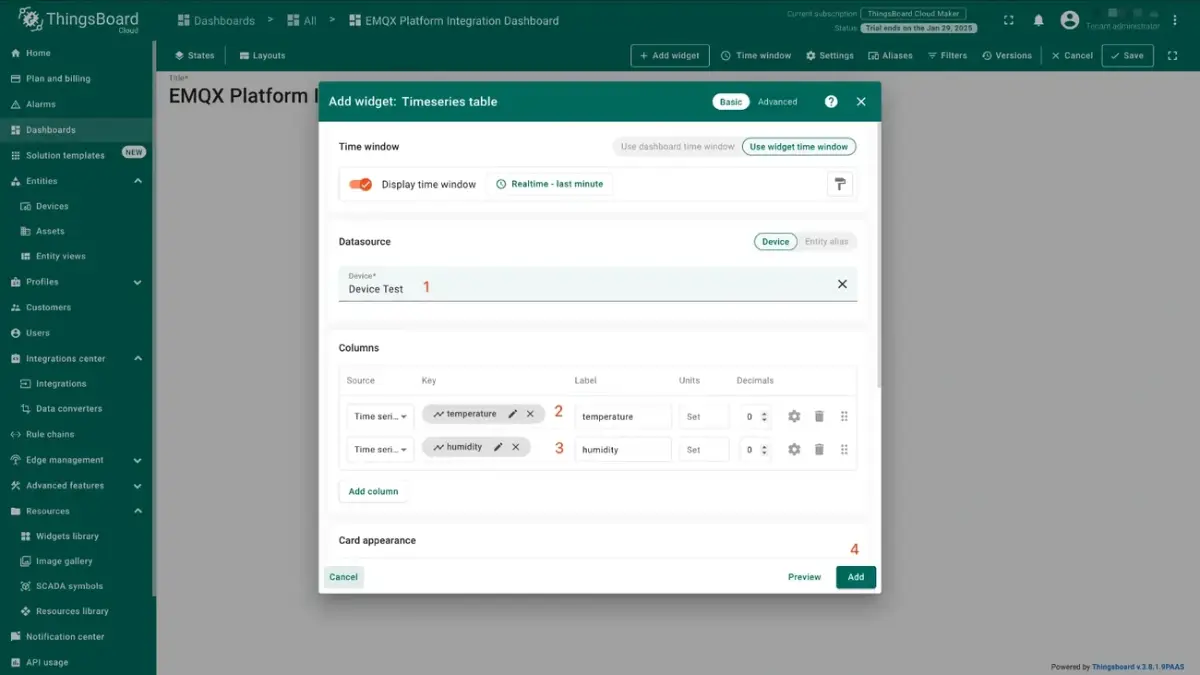

Open Source Tools: ThingsBoard, Node-RED

ThingsBoard gives users an open-source option to manage devices and see data. The platform works with standard protocols like MQTT, CoAP, and HTTP and runs both in cloud and on local servers. Users can customize dashboards with over 600 widgets to view live data.

Node-RED adds flow-based programming through a browser editor. Built with Node.js, this light software runs well on edge devices like Raspberry Pi. Users can create data flows between hardware and cloud services by dragging and dropping components.

Benefits and Performance Metrics of IoT Monitoring

IoT-based monitoring systems create measurable business outcomes in industries of all sizes. Companies that use these technologies see the most important improvements in their key operational areas.

Reduced Downtime via Predictive Alerts

Predictive maintenance stands out as one of IoT monitoring’s most valuable applications. Equipment sensors generate data that systems analyze to detect anomalies before catastrophic failures happen. Manufacturing facilities using predictive maintenance see a 5-15% reduction in downtime. Their maintenance costs drop by 18-25%. These benefits directly impact the bottom line since unplanned downtime costs industrial manufacturers approximately £39.71 billion each year.

Companies from a variety of sectors report remarkable results with IoT-powered predictive solutions. McKinsey’s research shows companies can slash maintenance costs by 40% and reduce downtime by up to 50%. Predictive maintenance in renewable energy has cut costs by 12% and boosted uptime by 9%.

Improved Operational Efficiency (KPI Tracking)

IoT monitoring changes how companies track system performance through continuous visibility. Live data helps teams spot inefficiencies and bottlenecks to optimize processes. Transportation companies that use IoT tracking systems report fuel costs dropping by 30% while productivity jumps 25%.

KPI monitoring makes proactive decision-making possible. Teams track equipment health indicators, availability percentages, latency measurements, and connection success rates. These metrics help organizations predict issues before operations suffer, which leads to 20-30% productivity gains across industries.

Scalability and Device Management at Scale

Modern IoT monitoring systems must grow with connected devices. Statistics show 152,000 devices will connect to the internet every minute by 2025. This growth demands flexible solutions that maintain performance.

Device management plays a vital role in scalable IoT deployments. Platforms like Cisco Spaces boost uptime through remote updates and health alerts. IT teams can spot issues early. These platforms offer one-click onboarding, remote configuration, and firmware-over-the-air updates. Such features help manage growing device fleets in various locations effectively.

Challenges in IoT Integration for Real-Time Systems

Organizations must deal with several implementation hurdles to maximize the effectiveness of IoT-based live monitoring systems, despite their many advantages.

Network Latency and Bandwidth Constraints

Time-sensitive IoT applications face critical latency challenges. System performance and safety can be compromised by even the smallest delays in autonomous vehicles or industrial automation. Live applications just need latency as low as 50ms for bidirectional response. Network congestion creates bandwidth bottlenecks that can lead to data loss, delays, and system disruptions. Applications with high data usage require substantial throughput, especially with live video streaming at high definitions.

Security and Data Privacy Concerns

Connected devices grow exponentially and expand the attack surface for potential breaches. Many IoT devices arrive with default credentials, no encryption, and limited patching capabilities. These vulnerabilities put both IT and OT systems at risk, as attackers target supply chains more frequently and insert backdoors into trusted assets. The right balance between convenience and security protocols helps prevent unauthorized access and data theft.

Interoperability Between Devices and Protocols

IoT ecosystems’ extreme heterogeneity causes interoperability problems. The wide range of communication protocols—including MQTT, CoAP, HTTP, Zigbee, and Z-Wave—makes smooth integration difficult. The biggest problem lies in IoT device connections that happen only during runtime, without prior design decisions to guide interoperability solutions. Different devices’ “capability mismatch” creates communication barriers that restrict effective system integration.

Conclusion

IoT integration has changed how we monitor systems in real-life across many industries. This article shows how sensor networks, edge computing, and specialized communication protocols create responsive monitoring environments together. Organizations now have better visibility into their operations and can respond to critical events faster.

A three-tiered architecture forms the foundation of continuous information flow through sensor nodes, IoT gateways, and data aggregators. Edge devices make this architecture better by processing data locally. This reduces latency for time-sensitive applications. The system also uses specialized protocols like MQTT and CoAP that optimize communication without compromising reliability.

Real-life applications show clear benefits of IoT monitoring. Manufacturing facilities cut downtime by 5-15% with predictive maintenance. Healthcare providers offer customized care by monitoring vital signs continuously. Energy companies improve grid reliability using distributed sensor networks. Transportation fleets save up to 30% in fuel costs with detailed tracking systems.

The supporting technology ecosystem keeps getting better. AWS IoT Core, Azure IoT Hub, Google Cloud IoT, and open-source options like ThingsBoard offer sophisticated platforms to manage devices and analyze data. Companies can scale their monitoring as device fleets grow while keeping performance steady.

The benefits are impressive, but challenges exist. Network latency creates issues for ultra-time-sensitive applications that need sub-50ms response times. Security vulnerabilities pose risks as attack surfaces grow. Different protocols and mismatched device capabilities make integration complex.

The future looks bright as organizations solve these problems through better design and innovation. Companies that welcome these systems gain advantages through improved efficiency, predictive maintenance, and analytical decision-making. Connected device adoption is growing toward billions of endpoints. Without doubt, live IoT monitoring will become crucial for modern operations across every industry.

Leave a Reply