Which Benchtop Spectrophotometer is the Best Choice in China?

3nh benchtop spectrophotometers, equipped with a self-developed differential spectrum engine and a dual-optical-path design with nanoscale gratings, achieve an industry-leading precision of dEab≤0.005, with a measurement deviation of only 0.01 over 30 days. Having served 50,000 customers worldwide and covered more than 30 industries including automotive and pharmaceuticals, 3nh reshapes the benchmark of domestic instruments with its high-performance core technologies.

In the field of color quality control for industrial manufacturing, the accuracy and stability of benchtop spectrophotometers directly determine product quality. Among numerous brands, threenh has emerged as a representative brand of domestic benchtop spectrophotometers, thanks to its solid technical accumulation and continuous innovation, and its comprehensive strength has been fully verified in market practice.

About the Threenh

The core competitiveness of threenh.com stems from its profound R&D accumulation. Founded in 1998, the company has built an R&D team composed of talents from prestigious universities such as Tsinghua University and China Jiliang University. Most core members hold doctoral degrees and senior professional titles, and the company maintains in-depth cooperation with authoritative institutions including the Guangdong Key Laboratory of South China Metrology Testing and Instrumentation. Over the years, 3nh has accumulated 5 US invention patents, multiple Chinese invention patents and software copyrights. A number of academic papers have been included in SCI and EI, forming a development model centered on independent technology research and development. This R&D system integrating industry, academia and research provides solid support for the technological breakthroughs of benchtop spectrophotometers.

Threenh benchtop spectrophotometers

In terms of core technologies and product performance, threenh benchtop spectrophotometers demonstrate outstanding advantages. The flagship TS82 series adopts the self-developed differential spectrum engine and dual-optical-path design with nanoscale gratings, which increases the light intake by 40% and the spectral resolution by 20%. The related technologies are all protected by invention patents. Among them, the TS8210 model achieves a repeatability of dEab≤0.025 and an inter-instrument agreement as low as dEab≤0.2. Under constant temperature conditions, the measurement deviation can be controlled within 0.03 over 30 days, and the deviation can be maintained within 0.3 even when the temperature changes from 0℃ to 40℃. The dual-optical-path design monitors the light source energy fluctuation while measuring the sample signal, effectively reducing environmental interference. The innovative MEMS process grating technology further improves the measurement accuracy at the nanoscale spectral resolution level.

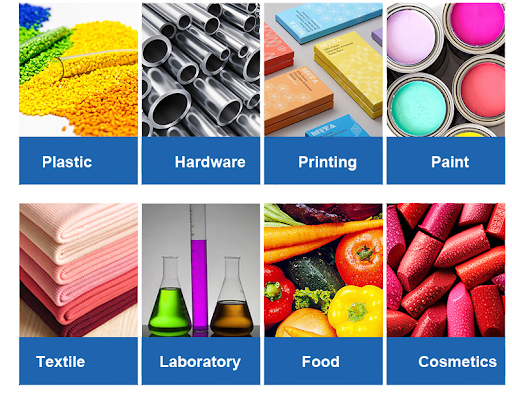

The product’s scenario adaptability also reflects its technical strength. 3NH benchtop spectrophotometers support both reflection and transmission measurement modes. In reflection mode, they are equipped with four auto-recognizable measuring apertures, which can easily handle various sample forms such as solids, powders and non-transparent liquids. The transmission mode can measure transparent materials such as glass and films with a thickness ≤ 50mm. Combined with a 1400dpi high-definition preview camera and brightness calibration algorithm, the spectrophotometers can truly restore the color of ultra-dark samples. Meanwhile, through the SQXC color quality control software, they realize synchronous storage and cloud management of data and images, meeting the quality control and color matching needs of multiple industries such as paint, plastic and textile.

Benchtop Spectrophotometers Application in Industry

Extensive industry applications and authoritative certifications have verified the brand strength. 3nh benchtop spectrophotometers have served more than 50,000 customers worldwide, covering over 30 industries, including Fortune Global 500 enterprises and well-known domestic scientific research institutions. In the auto parts industry, its equipment is used for car paint color difference control, helping automakers reduce the rework rate. In the pharmaceutical industry, the TS8560 model, with patented dual-optical-path compensation technology and constant temperature control technology, can meet the stringent requirements of injection solution testing. The company has successively obtained many honors including National High-tech Enterprise, Guangdong Provincial Science and Technology Progress Award, and “Top Domestic Instrument”. It has passed the ISO9001 quality management system certification, and its products comply with a number of international standards such as CIE, ISO and ASTM.

From technological R&D to market application, 3nh Technology has broken technical barriers through independent innovation. Its benchtop spectrophotometers have achieved breakthroughs in accuracy, stability and adaptability, making them a reliable choice among color difference testing instruments in China.

On-site Rapid Testing with Portable Colorimeters: Revolutionizing Traditional Color Management

Portable colorimeters are revolutionizing traditional color management models! The TS series products from 3nh Technology enable 1-second accurate color measurement on-site. Spanning industries from textile dyeing and printing to automotive manufacturing, these devices bring color detection out of the laboratory and onto the production line. This allows for real-time adjustment of process parameters, significantly reducing defect rates while boosting production efficiency and product quality.

In today’s diverse industries—ranging from textile dyeing and food packaging to automotive manufacturing and electronic products—precise color control is critical to product quality and brand image. Traditional color management relies heavily on laboratory testing, which involves cumbersome procedures and long turnaround times. The advent of portable colorimeters, especially the comprehensive product lineup from 3nh Technology (including models like the TS7700, YS45 series, and YS3060 series), provides a powerful tool for on-site rapid testing, gradually transforming conventional color management practices.

-

Overview of 3nh Portable Colorimeters

The TS77 series from 3nh Technology stands out as a flagship product line. Take the TS7700 as an example: it boasts exceptional inter-instrument agreement and repeatability, delivering accurate and reliable measurement data. Equipped with a full-spectrum LED light source covering 400–700 nm and four auto-recognizable measuring apertures, it meets the testing needs of a wide variety of samples. The device supports both computer-connected data processing and seamless integration with Android, iOS, and WeChat mini-programs, facilitating convenient data storage anytime, anywhere.

In terms of measurement architecture, the TS7700 features an innovative D/8 illumination design, compatible with two geometric conditions: Specular Component Included (SCI) and Specular Component Excluded (SCE). This enables precise capture of sample surface gloss data. With its built-in gloss correction model, the instrument effectively minimizes inter-device discrepancies caused by structural differences, delivering outstanding performance when measuring samples with varying surface properties, such as high-gloss and semi-gloss materials.

The YS45 series is engineered with a 45/0 annular illumination optical structure. Its innovative ring lighting system eliminates directional dependence, minimizing the impact of surface textures on measurement results. Building on the high-precision legacy of the TS7 series (ΔE*ab ≤ 0.04), the YS45 series balances performance with cost-effectiveness through streamlined functionality, making it an ideal choice for numerous industries. With a single measurement time of just 1.5 seconds, it dramatically enhances testing efficiency.

The YS30 series also offers robust functionality. Compact and highly portable, these devices are tailored for on-site rapid testing. They deliver excellent measurement accuracy, enabling quick and precise color difference detection to provide timely data support for quality control during production.

II. Portable Colorimeter Application Scenarios

1. Textile Dyeing and Printing Industry

Color consistency is paramount in textile dyeing and printing production lines. In traditional workflows, samples must be sent to laboratories for testing, and the waiting period for results often leads to the production of large batches of off-color products. With 3nh portable colorimeters (e.g., the TS7700 or ST70 series), workers can conduct on-site inspections of fabrics at any time. If color deviations are detected, dyeing process parameters can be adjusted immediately to prevent further defective products.

For instance, during the dyeing of a batch of blue fabric, a quick measurement with the TS7700 may reveal that the color is too light. Operators can then promptly increase dye dosage or adjust dyeing duration, ensuring uniform color across the entire batch and improving both product quality and production efficiency.

2. Printing and Packaging Industry

The accuracy of ink color directly impacts the quality of printed materials. 3nh portable colorimeters, such as the YS3060 and YD5050, enable rapid on-site testing of printed samples during production runs. Press operators can periodically measure the color of printed materials using the YS3060 and compare the results against standard color swatches. If color deviations exceed acceptable limits, parameters like ink ratio or printing pressure can be adjusted in real time, ensuring printed products match design specifications. This reduces waste caused by color inaccuracies and lowers production costs.

Printing Density Measurement

Density measurement is a widely used quality control method in the printing industry. It is recognized as the fastest, simplest, and most effective instrumental technique for inspecting and controlling printed product quality. A printing spectrodensitometer is a key instrument for printing quality control, whose core function is to quantify the color and density parameters of printed matter by measuring the light absorption characteristics of printing inks.

Color Density Measurement: Spectrodensitometers measure the color density values of printing inks (including CMYK and spot colors). Color density reflects the light absorption capacity of the ink film; higher density values typically indicate better color saturation. The calculation formula is:D=lg(1/R)where R represents reflectance.

Ink Film Thickness Control: Density values are closely correlated with ink film thickness (based on the Lambert-Beer Law). By measuring solid density, operators can adjust ink feed in real time to avoid over-inking or under-inking, ensuring consistent color reproduction.

Color Consistency Analysis: The instrument calculates hue error (H) and grayness (G), which help identify issues such as insufficient ink purity or excessive non-color components. This data supports the correction of color deviations (e.g., magenta shifting toward yellow).

The YD5050 series color densitometer is specifically designed for printing quality inspection, enhancing production efficiency and reducing costs.

3. Automotive Manufacturing Industry

Automotive body painting demands extremely high standards for color uniformity and consistency. The TS7700 spectrophotometer is well-suited for automotive coating lines: immediately after a vehicle body is painted, staff can perform on-site color measurements of the coating. The device captures both SCI and SCE data simultaneously, accurately acquiring coating surface gloss information. By comparing the measured data against standard color values, any deviations in color or gloss can be detected promptly. Operators can then adjust spraying parameters—such as spray gun angle and coating flow rate—to ensure every vehicle’s paint color meets stringent quality standards, elevating the overall appearance quality of the vehicles.

Special-effect coatings, from metallic finishes with brilliant luster to pearlescent paints with delicate textures, enhance the visual appeal of automotive exteriors but pose significant challenges for color consistency control. Traditional color measurement equipment struggles to capture color variations and special-effect parameters across multiple angles, leading to issues like color discrepancies and uneven sparkle in mass production, which undermine product quality and brand reputation.

The MS3012 multi-angle portable spectrophotometer addresses these challenges, providing a comprehensive color solution for the automotive manufacturing industry and serving as a core tool for inspecting special-effect automotive coatings. Equipped with 12 measuring angles (6 light sources + 2 detectors), the MS3012 accurately captures the color performance of automotive special-effect paints from different viewing angles.

III. Revolutionizing Traditional Color Management Models

Traditional color management relies on laboratory testing, which is time-consuming and prone to inefficient production. 3nh portable colorimeters enable on-site real-time detection and adjustment, are easy for operators to master, significantly boost efficiency, and reduce reliance on specialized technical personnel.

First, they shift color detection from the laboratory to the production line, enabling a closed-loop management system of real-time testing, feedback, and adjustment. Minimal training is required for operators to use the devices proficiently—whether they are experienced technicians or frontline production workers—greatly reducing dependence on specialized talent and shortening testing cycles.

Second, in terms of cost control, these instruments reduce defect and scrap rates. They eliminate the need for substantial laboratory investments and sample transportation costs, cutting enterprise expenses from multiple angles. Their data storage capabilities help enterprises establish color databases, providing valuable support for quality control and product development.

Furthermore, portable colorimeters play a positive role in supply chain collaboration. Suppliers can conduct self-inspections with these devices before shipping products to ensure color compliance with purchasers’ requirements. Purchasers can also perform on-site rapid inspections upon receiving goods, avoiding disputes and returns caused by color mismatches and improving overall supply chain efficiency.

Conclusion

In summary, 3nh benchtop spectrophotometer and portable colorimeters comprehensively revolutionize traditional color management models across dimensions including testing efficiency, cost control, data management, and supply chain collaboration, bringing unprecedented convenience and improvement to color management in various industries.

Leave a Reply